Page 395 - 2019 SHOP MANUAL CRF1000/A/D

P. 395

dummyheadmmyhead

du

CRANKSHAFT/PISTON/CYLINDER

INSPECTION

Inspect the following parts for scratches, damage,

abnormal wear, or deformation.

– Cylinder

–Piston

– Piston rings

– Piston pin

– Connecting rod small end

Measure each part and calculate the clearance

according to CRANKSHAFT/PISTON/CYLINDER

SPECIFICATIONS (page 1-9).

Replace any part if it is out of service limit.

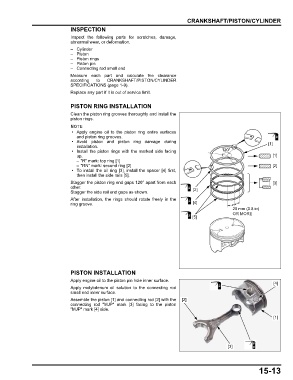

PISTON RING INSTALLATION

Clean the piston ring grooves thoroughly and install the

piston rings.

• Apply engine oil to the piston ring entire surfaces

and piston ring grooves.

• Avoid piston and piston ring damage during [1]

installation.

• Install the piston rings with the marked side facing 120°

up. [1]

– "R" mark: top ring [1]

– "RN" mark: second ring [2] [2]

• To install the oil ring [3], install the spacer [4] first,

then install the side rails [5].

Stagger the piston ring end gaps 120° apart from each [3]

other.

Stagger the side rail end gaps as shown. [2]

After installation, the rings should rotate freely in the

ring groove. [4]

20 mm (0.8 in)

OR MORE

[5]

PISTON INSTALLATION

Apply engine oil to the piston pin hole inner surface.

[4]

Apply molybdenum oil solution to the connecting rod

small end inner surface.

Assemble the piston [1] and connecting rod [2] with the [2]

connecting rod "MJP" mark [3] facing to the piston

"MJP" mark [4] side.

[1]

[3]

15-13