Page 391 - 2019 SHOP MANUAL CRF1000/A/D

P. 391

dummyheadmmyhead

du

CRANKSHAFT/PISTON/CYLINDER

CRANKPIN BEARING

Do not interchange the bearing inserts. They must be

installed in their original locations or the correct bearing

oil clearance may not be obtained, resulting in engine

damage.

Remove the crankshaft (page 15-4).

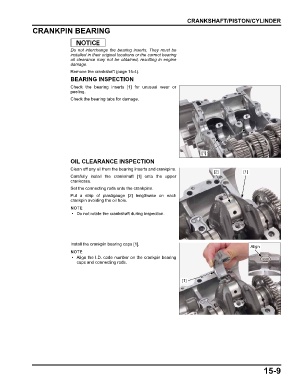

BEARING INSPECTION

Check the bearing inserts [1] for unusual wear or

peeling.

Check the bearing tabs for damage.

[1]

OIL CLEARANCE INSPECTION

Clean off any oil from the bearing inserts and crankpins.

[2] [1]

Carefully install the crankshaft [1] onto the upper

crankcase.

Set the connecting rods onto the crankpins.

Put a strip of plastigauge [2] lengthwise on each

crankpin avoiding the oil hole.

• Do not rotate the crankshaft during inspection.

Install the crankpin bearing caps [1].

Align

• Align the I.D. code number on the crankpin bearing

caps and connecting rods.

[1]

15-9