Page 392 - 2019 SHOP MANUAL CRF1000/A/D

P. 392

dummyheadmmyhead

du

CRANKSHAFT/PISTON/CYLINDER

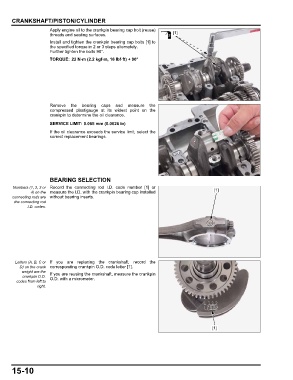

Apply engine oil to the crankpin bearing cap bolt (reuse)

threads and seating surfaces. [1]

Install and tighten the crankpin bearing cap bolts [1] to

the specified torque in 2 or 3 steps alternately.

Further tighten the bolts 90°.

TORQUE: 22 N·m (2.2 kgf·m, 16 lbf·ft) + 90°

Remove the bearing caps and measure the

compressed plastigauge at its widest point on the

crankpin to determine the oil clearance.

SERVICE LIMIT: 0.065 mm (0.0026 in)

If the oil clearance exceeds the service limit, select the

correct replacement bearings.

BEARING SELECTION

Numbers (1, 2, 3 or Record the connecting rod I.D. code number [1] or

4) on the measure the I.D. with the crankpin bearing cap installed [1]

connecting rods are without bearing inserts.

the connecting rod

I.D. codes.

Letters (A, B, C or If you are replacing the crankshaft, record the

D) on the crank corresponding crankpin O.D. code letter [1].

weight are the If you are reusing the crankshaft, measure the crankpin

crankpin O.D. O.D. with a micrometer.

codes from left to

right.

[1]

15-10