Page 389 - 2019 SHOP MANUAL CRF1000/A/D

P. 389

dummyheadmmyhead

du

CRANKSHAFT/PISTON/CYLINDER

Install the lower crankcase onto the upper crankcase.

Make sure that the upper and lower crankcase are

seated securely.

Apply molybdenum oil solution to the crankcase main

journal bolt threads and seating surfaces. [1]

Install the crankcase main journal bolts [1].

Tighten the bolts in a crisscross pattern in 2 or 3 steps

to the specified torque.

TORQUE:43 N·m (4.4 kgf·m, 32 lbf·ft)

Remove the bolts and lower crankcase.

Measure the compressed plastigauge at its widest point

on each main journal to determine the oil clearance.

SERVICE LIMIT: 0.05 mm (0.002 in)

If the oil clearance exceeds the service limit, select a

replacement bearing.

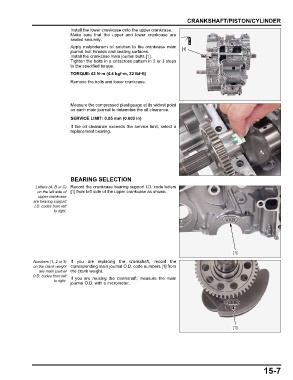

BEARING SELECTION

Letters (A, B or C) Record the crankcase bearing support I.D. code letters

on the left side of [1] from left side of the upper crankcase as shown.

upper crankcase

are bearing support

I.D. codes from left

to right.

[1]

Numbers (1, 2 or 3) If you are replacing the crankshaft, record the

on the crank weight corresponding main journal O.D. code numbers [1] from

are main journal the crank weight.

O.D. codes from left If you are reusing the crankshaft, measure the main

to right.

journal O.D. with a micrometer.

[1]

15-7