Page 91 - 2019 SHOP MANUAL CRF1000/A/D

P. 91

dummyheadmmyhead

du

MAINTENANCE

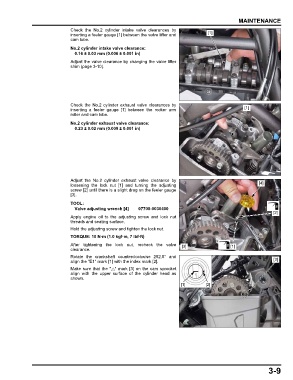

Check the No.2 cylinder intake valve clearances by

inserting a feeler gauge [1] between the valve lifter and [1]

cam lobe.

No.2 cylinder intake valve clearance:

0.16 ± 0.03 mm (0.006 ± 0.001 in)

Adjust the valve clearance by changing the valve lifter

shim (page 3-10).

Check the No.2 cylinder exhaust valve clearances by

inserting a feeler gauge [1] between the rocker arm [1]

roller and cam lobe.

No.2 cylinder exhaust valve clearance:

0.23 ± 0.02 mm (0.009 ± 0.001 in)

Adjust the No.2 cylinder exhaust valve clearance by

loosening the lock nut [1] and turning the adjusting [4]

screw [2] until there is a slight drag on the feeler gauge

[3].

TOOL:

Valve adjusting wrench [4] 07708-0030400

[2]

Apply engine oil to the adjusting screw and lock nut

threads and seating surface.

Hold the adjusting screw and tighten the lock nut.

TORQUE: 10 N·m (1.0 kgf·m, 7 lbf·ft)

After tightening the lock nut, recheck the valve [3] [1]

clearance.

Rotate the crankshaft counterclockwise 252.5° and

align the "E1" mark [1] with the index mark [2]. [3]

Make sure that the " " mark [3] on the cam sprocket

align with the upper surface of the cylinder head as

shown.

[1] [2]

3-9