Page 362 - 2019 SHOP MANUAL CRF1000/A/D

P. 362

dummyheadmmyhead

du

CRANKCASE/TRANSMISSION/BALANCER

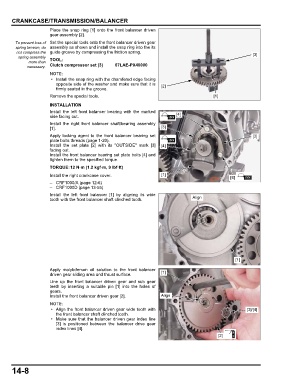

Place the snap ring [1] onto the front balancer driven

gear assembly [2].

To prevent loss of Set the special tools onto the front balancer driven gear

spring tension, do assembly as shown and install the snap ring into the its

not compress the guide groove by compressing the friction spring. [3]

spring assembly TOOL:

more than

necessary. Clutch compressor set [3] 07LAE-PX40000

• Install the snap ring with the chamfered edge facing

opposite side of the washer and make sure that it is [2]

firmly seated in the groove.

Remove the special tools. [1]

INSTALLATION

Install the left front balancer bearing with the marked

side facing out. [4]

Install the right front balancer shaft/bearing assembly

[1]. [3]

Apply locking agent to the front balancer bearing set [2]

plate bolts threads (page 1-20).

Install the set plate [2] with its "OUTSIDE" mark [3] [4]

facing out.

Install the front balancer bearing set plate bolts [4] and

tighten them to the specified torque.

TORQUE:12 N·m (1.2 kgf·m, 9 lbf·ft)

Install the right crankcase cover. [1] [4]

– CRF1000/A (page 12-6)

– CRF1000D (page 13-55)

Install the left front balancer [1] by aligning its wide

tooth with the front balancer shaft clinched tooth. Align

[1]

Apply molybdenum oil solution to the front balancer

driven gear sliding area and thrust surface. [1]

Line up the front balancer driven gear and sub gear

teeth by inserting a suitable pin [1] into the holes of

gears.

Install the front balancer driven gear [2]. Align

• Align the front balancer driven gear wide tooth with [3]/[4]

the front balancer shaft clinched tooth.

• Make sure that the balancer driven gear index line

[3] is positioned between the balancer drive gear

index lines [4].

[2]

14-8