Page 366 - 2019 SHOP MANUAL CRF1000/A/D

P. 366

dummyheadmmyhead

du

CRANKCASE/TRANSMISSION/BALANCER

If you are replacing the rear balancer driven gear and/or

needle bearing, record the corresponding balancer

driven gear I.D. code [1] from the balancer weight.

If you are reusing the rear balancer driven gear,

measure the balancer journal I.D. with a micrometer.

Cross-reference the balancer journal I.D. and needle

bearing codes to determine the replacement needle

bearing color code [1].

NEEDLE BEARING O.D.:

91015-MJP-G510-M1:Thickest

91016-MJP-G510-M1:

91017-MJP-G510-M1:Thinnest [1]

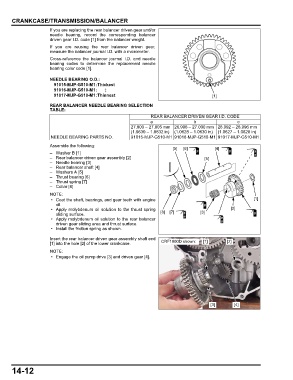

REAR BALANCER NEEDLE BEARING SELECTION

TABLE:

REAR BALANCER DRIVEN GEAR I.D. CODE

a b c

27.000 – 27.005 mm 26.996 – 27.000 mm 26.992 – 26.996 mm

(1.0630 – 1.0632 in) (1.0628 – 1.0630 in) (1.0627 – 1.0628 in)

NEEDLE BEARING PARTS NO. 91015-MJP-G510-M1 91016-MJP-G510-M1 91017-MJP-G510-M1

Assemble the following:

[5] [6] [4]

–Washer B [1]

– Rear balancer driven gear assembly [2] [5]

– Needle bearing [3]

– Rear balancer shaft [4]

– Washers A [5]

– Thrust bearing [6]

– Thrust spring [7]

–Collar [8]

• Coat the shaft, bearings, and gear teeth with engine [1]

oil.

• Apply molybdenum oil solution to the thrust spring [2]

sliding surface. [8] [7] [3]

• Apply molybdenum oil solution to the rear balancer

driven gear sliding area and thrust surface.

• Install the friction spring as shown.

Insert the rear balancer driven gear assembly shaft end

[1] into the hole [2] of the lower crankcase. CRF1000D shown: [1] [2]

• Engage the oil pump drive [3] and driven gear [4].

[3] [4]

14-12