Page 381 - 2019 SHOP MANUAL CRF1000/A/D

P. 381

dummyheadmmyhead

du

CRANKCASE/TRANSMISSION/BALANCER

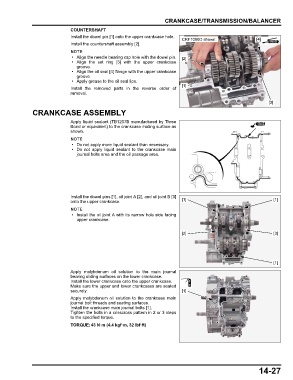

COUNTERSHAFT

Install the dowel pin [1] onto the upper crankcase hole.

CRF1000D shown: [4]

Install the countershaft assembly [2].

• Align the needle bearing cap hole with the dowel pin. [2]

• Align the set ring [3] with the upper crankcase

groove.

• Align the oil seal [4] flange with the upper crankcase

groove.

• Apply grease to the oil seal lips.

[1]

Install the removed parts in the reverse order of

removal.

[3]

CRANKCASE ASSEMBLY

Apply liquid sealant (TB1207B manufactured by Three

Bond or equivalent) to the crankcase mating surface as

shown.

• Do not apply more liquid sealant than necessary.

• Do not apply liquid sealant to the crankcase main

journal bolts area and the oil passage area.

Install the dowel pins [1], oil joint A [2], and oil joint B [3]

onto the upper crankcase. [1] [1]

• Install the oil joint A with its narrow hole side facing

upper crankcase.

[2] [3]

[1]

Apply molybdenum oil solution to the main journal

bearing sliding surfaces on the lower crankcase.

Install the lower crankcase onto the upper crankcase.

Make sure the upper and lower crankcases are seated

securely. [1]

Apply molybdenum oil solution to the crankcase main

journal bolt threads and seating surfaces.

Install the crankcase main journal bolts [1].

Tighten the bolts in a crisscross pattern in 2 or 3 steps

to the specified torque.

TORQUE:43 N·m (4.4 kgf·m, 32 lbf·ft)

14-27