Page 290 - 2019 SHOP MANUAL CRF1000/A/D

P. 290

du

dummyheadmmyhead

DUAL CLUTCH TRANSMISSION (DCT) (CRF1000D)

DTC 21-2 (SHIFT SPINDLE ANGLE

SENSOR HIGH VOLTAGE)

1. Shift Spindle Angle Sensor System Inspection

Check the shift spindle angle sensor with the MCS.

Is about 5 V indicated?

YES – GO TO STEP 2.

NO – Intermittent failure

2. Shift Spindle Angle Sensor Inspection

Replace the shift spindle angle sensor with a known

good one (page 13-79).

Check the shift spindle angle sensor with the MCS.

Is about 5 V indicated?

YES – Replace the PCM with a known good one

(page 4-39) and recheck.

NO – Faulty original shift spindle angle sensor

DTC 22-1 (SHIFT SPINDLE

OPERATION MALFUNCTION: AFTER

OPERATING GEARSHIFT

MECHANISM)

1. Shift Spindle Angle Sensor System Inspection

Check the shift spindle angle sensor with the MCS.

Is Low voltage (about 0 V) or High voltage (about

5 V) indicated?

YES – • About 0 V: See DTC 21-1 (page 13-18).

• About 5 V: See DTC 21-2 (page 13-20).

NO – GO TO STEP 2.

2. Shift Control Motor/Reduction Gear Condition

Check the shift control motor and reduction gears

are installed properly and are not damaged (page

13-71).

Are the shift control motor and reduction gears

in normal condition?

YES – GO TO STEP 3.

NO – Install the shift control motor and reduction

gears properly or replace faulty parts.

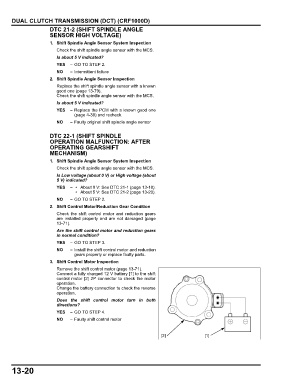

3. Shift Control Motor Inspection

Remove the shift control motor (page 13-71).

Connect a fully charged 12 V battery [1] to the shift

control motor [2] 2P connector to check the motor

operation.

Change the battery connection to check the reverse

operation.

Does the shift control motor turn in both

directions?

YES – GO TO STEP 4.

NO – Faulty shift control motor

[2] [1]

13-20