Page 338 - 2019 SHOP MANUAL CRF1000/A/D

P. 338

du

dummyheadmmyhead

DUAL CLUTCH TRANSMISSION (DCT) (CRF1000D)

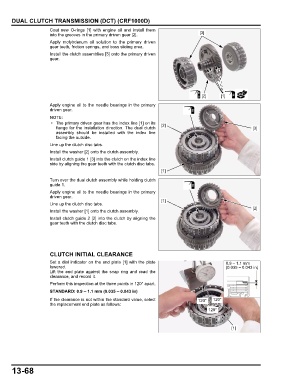

Coat new O-rings [1] with engine oil and install them

into the grooves in the primary driven gear [2]. [3]

Apply molybdenum oil solution to the primary driven

gear teeth, friction springs, and boss sliding area.

Install the clutch assemblies [3] onto the primary driven

gear.

[2] [1]

Apply engine oil to the needle bearings in the primary

driven gear.

• The primary driven gear has the index line [1] on its [2]

flange for the installation direction. The dual clutch [3]

assembly should be installed with the index line

facing the outside.

Line up the clutch disc tabs.

Install the washer [2] onto the clutch assembly.

Install clutch guide 1 [3] into the clutch on the index line

side by aligning the gear teeth with the clutch disc tabs.

[1]

Turn over the dual clutch assembly while holding clutch

guide 1.

Apply engine oil to the needle bearings in the primary

driven gear.

[1]

Line up the clutch disc tabs.

[2]

Install the washer [1] onto the clutch assembly.

Install clutch guide 2 [2] into the clutch by aligning the

gear teeth with the clutch disc tabs.

CLUTCH INITIAL CLEARANCE

Set a dial indicator on the end plate [1] with the plate 0.9 – 1.1 mm

lowered. (0.035 – 0.043 in)

Lift the end plate against the snap ring and read the

clearance, and record it.

Perform this inspection at the three points in 120° apart.

STANDARD: 0.9 – 1.1 mm (0.035 – 0.043 in)

If the clearance is not within the standard value, select 120° 120°

the replacement end plate as follows:

120°

[1]

13-68